TeknoMix ploughshare mixer is one of our three types of tubulent powder mixers. The other one is paddle and ribbon mixer.

Similar to ribbon mixer, ploughshare mixer is so versatile that it can handle nearly all types of materials including drying material, powdery granular, short fibered substance, moist solids with liquids, higly viscous masses and pasty material.

TeknoMix ploughshare mixer can be used for numerous processes, including, granulating, breaking down agglomerates compounding, fine mixing, dispersing, suspending, emulsifying, deaerating, tempering, accelerating chemical or physical reactions, etc. It is particularly suited for such difficult processes as mixing trace elements in proportions of 1 in 100,000 to 1 in 1,000,000 parts.

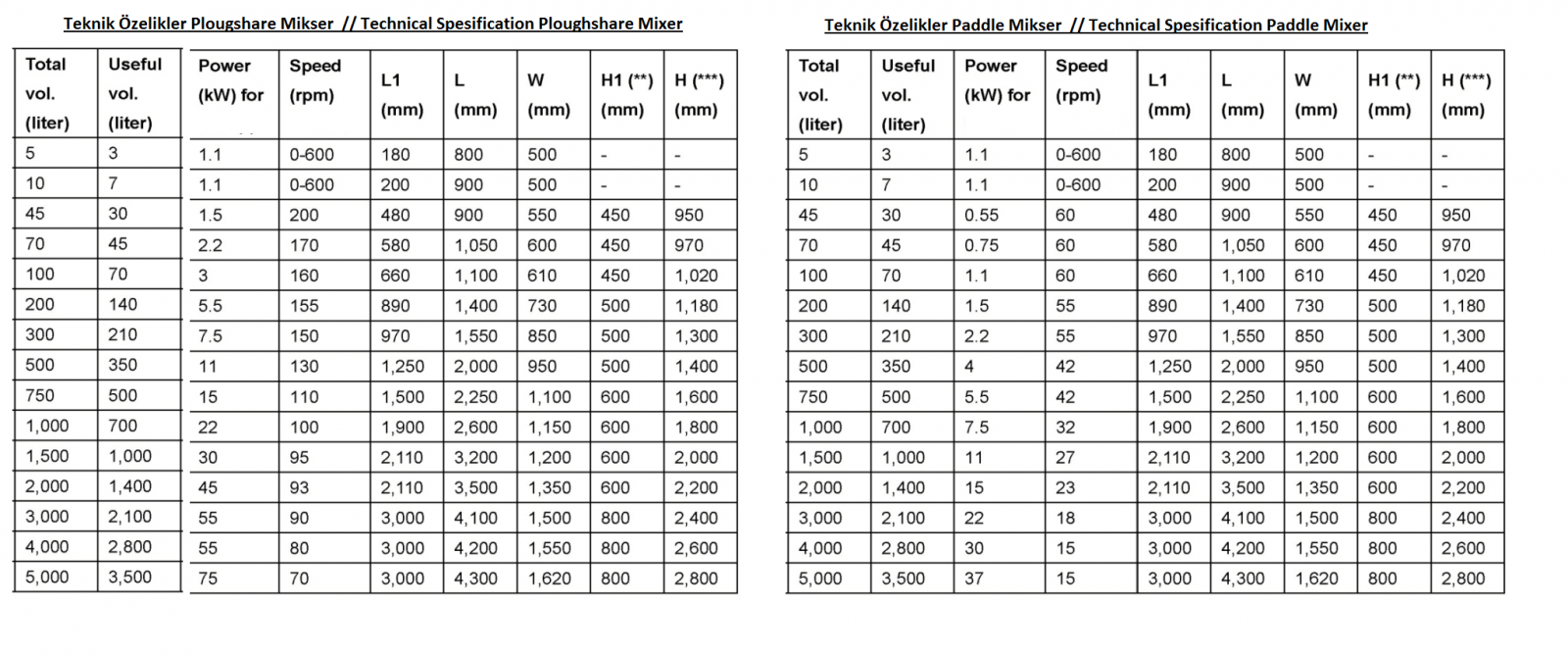

The mixing container is filled from 30% to 75% capacity, allowing space for individual particles to be dispersed within the main area of the mixer. The plough shaped mixing elements create intense axial and radial movements causing the product to move throughout the mixing space. The shape and angle, together with the adjustment and rotation of the mixing elements and drum wall, cause the product to be lifted off the surface of the drum wall. The product is automatically discharged while the machine is still running so that any separation is prevented.

Constructions:

Ploughshare Mixer consists of a centrally mounted horizontal shaft that rotates within a cylindrical drum container, ploughs or other shaped mixing elements are attached to the centrally fixed shafts, special openings at the top for feeding materials, flush fitting access doors at the front of the mixer, a fitting discharge valve at the bottom of the mixer which is pneumaticly or manually operated, and a complete driving unit.

Lab & Pilot Applications:

PerMix is able to offer lab - pilot size ploughshare mixers for research & development purpose. The small size machine is very helpful for customers when the ingredients for R&D are expensive, and to meet the badget limit at the first stage. With the good performance of the lab & pilot mixer, it is easy to scale up for a medium size or even bigger one.

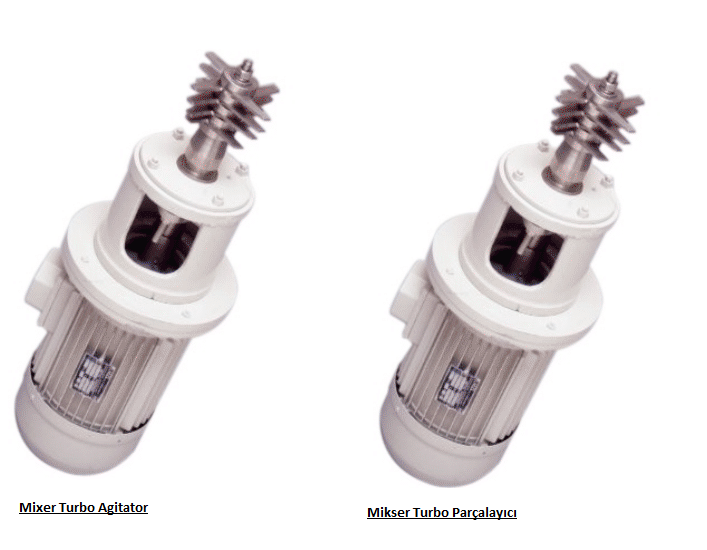

The installation of turbo chopper in the basic powder mixer enables the breaking down of agglomerates during the mixing processes. Together with the mixing element, the turbo multi-aggitators removes lumps in the initial product, chops pasty adhesives and hinders the formation of agglomeration during the moisturizing of powdered substances. The PerMix Multi-chopper is operated independently by its own motor.

Feeding & Discharging

A variety of feeding and discharging methods can be selected by the customers.

Other Features:

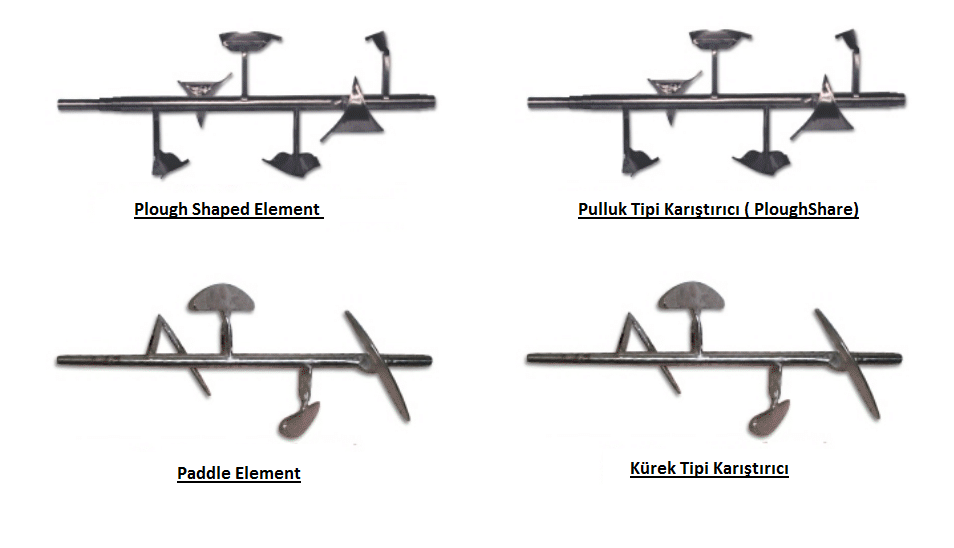

Different types of mixing element for different materials. TeknoConvey provides mainly three types of mixing elements – plough, ribbon and padde . Both have their advantages: the plough shaped element can easily penetrate through the dense and thick powder or paste materials, while the paddle element can cover an even wider range of viscousity.

Construction material

We are able to offer mixers with contact part to be built by Carbon steel, SS304, SS316/316L, titanium, duplex stainless steel, hastelloy. For abrasive materials we offer hardened steel as the contact part lifo tungsten carpite. Also we produce mixers all by stainless steel in order to meet the high hygienic requirement.

Drive system

Inverter, drive system by geared motor, cycloidal reducer, worm reducer, belt or chain transmission, etc.

Continous operation

We can supply machines for continuous work when a large capacity per hour is needed for the same material.

Vacuum drying and deaerating

The mixer can be designed for vacuum drying and deaerating for special applications.

Heating/Cooling jacket

Jacketed trough for heating or cooling operation

Applications:

TeknoMix ploughshare mixer has a wide range of applications:

Paste mixing: dough, PVC pastes, car body fillers putties, sugar, marzipan paste, biscuit creams, toiletry pastes, tile adhesives and grouts

Dry powder mixing: Food flavoring/additives, sponge/cake mixes, cosmetics, pharmaceuticals, cement, powdered rubber

Mixing of wet slurries: Filter cake re-slurrying, dough, fiber glass resin dough putty

Wet granulation; Liquid coating of powders and granules

Fat and oil incorporation

TeknoMix paddle mixer is an innovative design of the conventional ploughshare mixerbut it generates gentler mixing) and requires less power consumption.

Besides, the paddle mixer has a better performance when the materials are with liquid and viscous, for example, slurries, this is because the conventional plough mixing elements tend to be sticked and wrapped by the viscous materials while the new paddle agitator doesn’t.

The main differene between our Paddle Mixer and Ploughshare Mixer is the mixing element that is used: PLoughshare Mixer uses the plough shaped element, while Paddle Mixer uses the paddle element.

Lab & Pilot Applications:

PerMix is able to offer lab - pilot size ploughshare mixers for research & development purpose. The small size machine is very helpful for customers when the ingredients for R&D are expensive, and to meet the badget limit at the first stage. With the good performance of the lab & pilot mixer, it is easy to scale up for a medium size or even bigger one.

Special Design with Multi-aggitators:

The installation of turbo chopper in the basic powder mixer enables the breaking down of agglomerates during the mixing processes. Together with the mixing element, the turbo multi-aggitators removes lumps in the initial product, chops pasty adhesives and hinders the formation of agglomeration during the moisturizing of powdered substances. The PerMix Multi-chopper is operated independently by its own motor.

Other Features:

Different types of mixing element for different materials

TeknoConvey provides mainly two types of mixing elements plough and padde. Both have their advantages: the plough shaped element can easily penetrate through the dense and thick powder or paste materials, while the paddle element can cover an even wider range of viscousity.

Construction material

We are able to offer mixers with contact part to be built by Carbon steel, SS304, SS316/316L, titanium, duplex stainless steel, hastelloy. For abrasive materials we offer hardened steel as the contact part lifo tungsten carpite. Also we produce mixers all by stainless steel in order to meet the high hygienic requirement.

Feeding & Discharging

A variety of feeding & discharging methods can be selected by the customers.

Continous operation

We can supply machines for continuous work when a large capacity per hour is needed for the same material. Continuous ploughshare mixers differ from batch ploughshare mixers in that the mass flow of the product is from the inlet of the container to the discharge at the opposite end.

Heating/Cooling jacket

Jacketed trough for heating/cooling operation

Extended height bases

Height of our Ribbon Mixer can be defined according to customer’s condition.

Vacuum drying and deaerating

The mixer can be designed for vacuum drying & deaerating for special applications.

Drive system

Drive system by geared motor, cycloidal reducer, worm reducer, belt or chain transmission, etc.

Spray nozzle

Liquid can be added into the powder by spray nozzles on the top.

Applications:

Paddle Mixer can be used wherever the Ploughshare Mixer is used, including but not limited to compounding, fine mixing, dispersing, suspending, emulsifying, deaerating, tempering, accelerating chemical or physical reactions, granulating, breaking down agglomerates, etc. It is suited for such difficult processes as mixing trace elements in proportions of 1 in 100,000 to 1 in 1,000,000 parts.

Mixing Dryer And Reactor:

With some special modification, the TeknoMix Paddle Mixer can be used as a multi-stage process vessel eliminating the need for additional specialist equipment. It can be used as a mixer dryer, mixer-granulator, de-aerator, reactor and cooler.

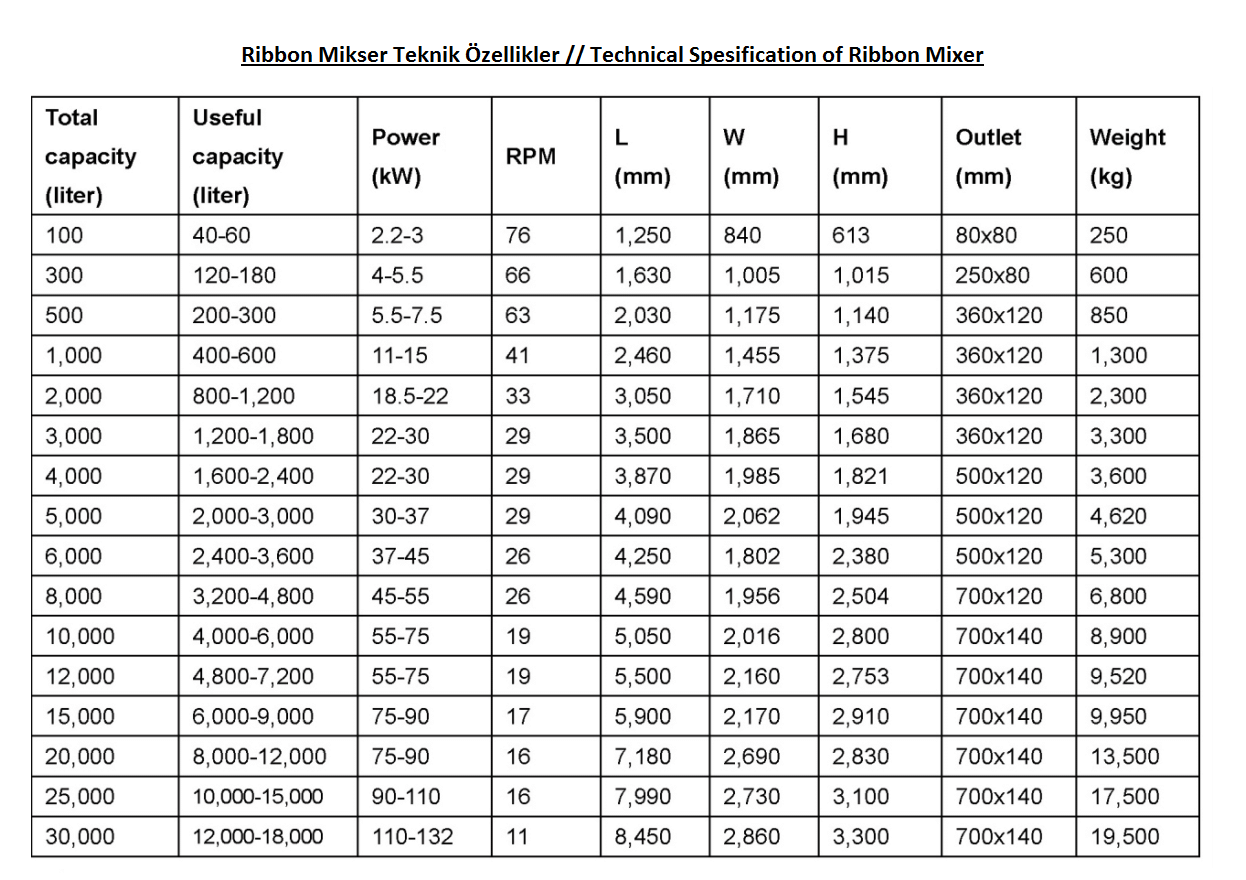

Ribbon Mixers are versatile and efficient mixing and blending machines for mixing of granules, dry powders, and viscous pastes homogeneously. They are able to give perfect result for mixing due to the innovative design of spiral agitator inside of its U shape chamber.

In a Ribbon Mixer, the powder or paste moves from center to the end of container and also from end to the center. In such a three dimensional way, the total powder or paste is mixed within the chamber. It asks for a short mixing time and relatively low power consumption.

The unit consists of one electrical motor, one reduction gear, coupling, and shaft with spiral agitator. The shaft is sealed with bush and gland housing at both ends. Materials are loaded from top side, and the discharge is located at the bottom side in the center. The discharge height can be adjusted as per requirement, so that material gets discharged into the container below it without floating dust.

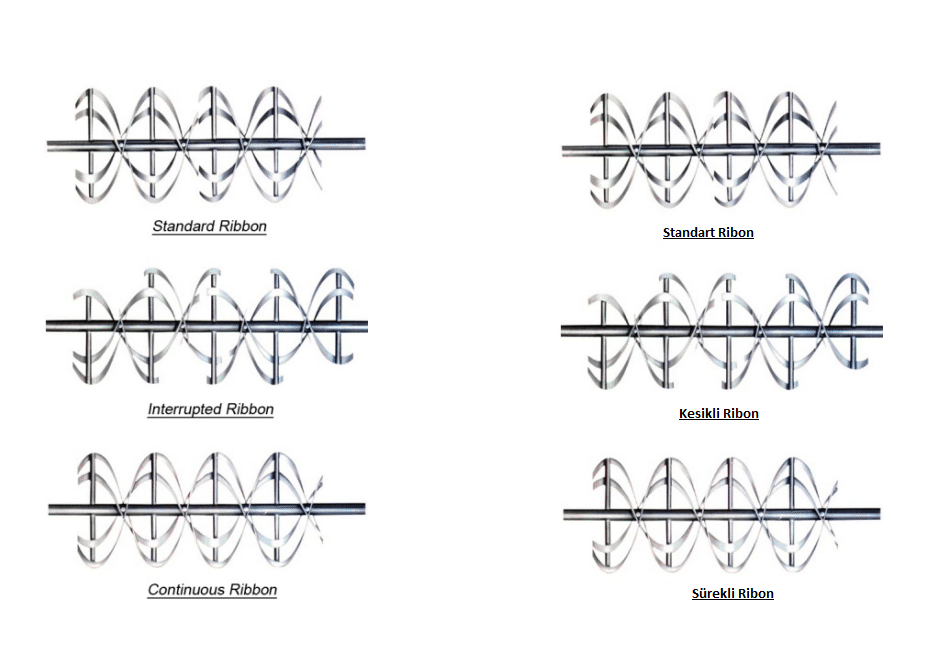

Ribbon

We con provide so many types of spiral ribbon for different sizes and applications.

Construction material

We are able to offer Ribbon Mixers with contact part to be built by carbon steel, SS304, SS316/316L, titanium, duplex stainless steel, hastelloy, etc. For abrasive materials we offer hardened steel as the contact part. Also we produce Ribbon Mixers all by stainless steel in order to meet the high hygienic requirement.

Feeding & Discharging

A variety of feeding & discharging methods can be selected by the customers. For feeding of materials, bag dump station can be mounted on the top of the U-shaped trough. Safety grid can be installed to prevent the possible injury to the worker. For discharge of the products, manual, pneumatic, or motorized operated valves can be selected according to the customers' preference. They are prepared to fit into any existing production line easily.

Drive system

Drive system by geared motor, cycloidal reducer, worm reducer, belt or chain transmission, etc.

Heating/Cooling jacket

Jacketed trough for heating/cooling operation

Vacuum drying and deaerating

The mixer can be designed for vacuum drying and deaerating for special applications.

Spray nozzle

Liquid can be added into the powder by spray nozzles on the top.

Extended height bases

Height of our Ribbon Mixer can be defined according to customer’s condition.

Special Design of Motorized Tilting:

TeknoMix has designed a special feature for food application with motorized tilting for discharge. The machine is built in full stainless steel construction for wash cleaning, a top lid with counterweight for easy manual opening.