Industrial Vacuum Cleaners

TeknoConvey non-stop operation of the pneumatic vacuum allow you to efficiently vacuum each day with high vacuum power, it can suck from 80 – 100 meters. No moving internal parts grealy minimize maintanance. This machine is ideal for both intermittent and continuous operation. At only65- 70 dBA, this machine can be used in noise sensitive areas anytime of the day. TeknoConvey air-operated industrial vacuums offer operators tremendous versatility, all in a safe and powerful overall package. TeknoConvey industrial vacuums cleaners are the optimal solution for maintenance, cleaning and production automation.They are helpful for cleaning in confined areas and for the removal of hazardous dust and fumes.

TeknoConvey compressed air industrial vacuums have been designed to operate whenever electricity is unavailable or forbidden by (for example) ATEX directives. Equipped with Venturi systems, TeknoConvey compressed air industrial vacuums are ideal for recovering both solid debris and liquid spills. They are available in painted steel, stainless steel and as flameproof ATEX-compliant.

TeknoConvey Vacuum Cleaner easy to use compressed air industrial vacuum. Conceived to be used where electricity is unavailable or forbidden, it is equipped with a new technology of multistage vacuum generator system.

The compressed air vacuums grant respect for the environment and the most safety level for the operators. Thanks to the new generation multistage vacuum system, it guarantees good performances with the lowest air consumption ever, thus leading to a substantial cost and energy saving. Compact and light vacuum cleaner is equipped with a 37 l container. This unit can be delivered painted or stainless steel.

TeknoConvey vacuum cleaner is always equipped with a pressure gauge. Our Vacuum cleaner is the ideal industrial vacuum for shipyards, metalworking companies, oil refineries, chemical industries, spray painting facilities, rifle ranges applications, as well as in the food industry, whenever in presence of static electricity (working with sugar or flour), on building sites, and during surface treatment operations.

- Compact dimensions

- High container capacity

- Energy saving

- Halved compressed air consumption

- Quick return on investment

- Less shutdowns on ordinary mantainance

- Pressure gauge

- Stainless steel version available

- Upstream HEPA filter available

| Technical Data | |

| Air flow | 4.000 Lt / Minute |

| Vacuum (kPa) | 70 Kpa ( – 700mbar) |

| Container capacity (lt) | 30 Lt |

| Filter area | 0.7 m^2 |

| Sound pressure level (dB(A)) | 70 |

| Weight (kg) | 75 |

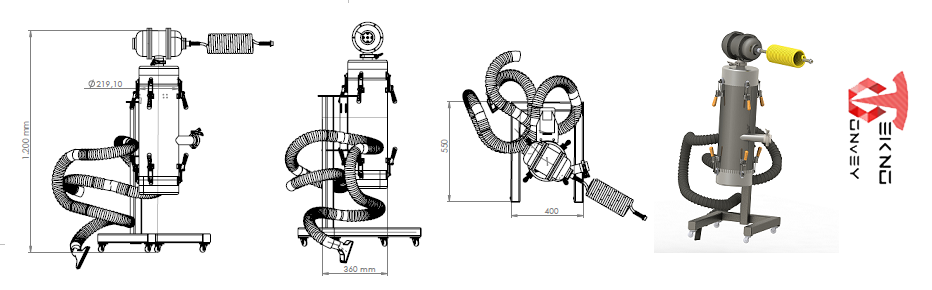

| Dimensions (L x W x H) | 55 cm x 40cm x120cm |

| Compressed air supply (min.) psi (bar) 2-6 | 800-1200 Lt / Minute |

TeknoConvey explosion proof air operated penumatic vacuum cleaners are safe for use in hazardous locations as part of a combustible dust control program and are suitable for many flammable and combustible materials. Our vacuums are manufactured under the ATEX directive that the European Union uses as a standard. These standards contain the standards for of equipment approved for use in explosive atmospheres.

TeknoConvey explosion proof air operated penumatic vacuum cleaners are safe for use in hazardous locations as part of a combustible dust control program and are suitable for many flammable and combustible materials. Our vacuums are manufactured under the ATEX directive that the European Union uses as a standard. These standards contain the standards for of equipment approved for use in explosive atmospheres.

When working with combustible dusts, flammable substances or materials with a tendency to build static electricity during conveyance, it is strongly recommended to choose our explosion-proof option when ordering. Our systems have no motors to arc or moving parts that can create friction or sparks. TeknoConveyare non electric, explosion-proof vacuums that are a safe, reliable and cost effective solution for your factory.

Pneumatic ejector pump vacuum cleaners bond all components of the vacuum together, ensuring no part is left isolated from its path to ground. When used in conjunction with our static conductive hose, a TeknoConvey explosion proof vacuum is an economical alternative to our competitor’s products which often sell for many times our cost.

Performance is not compromised by explosion proof safeguards, Explosion proof vacuums will perform with the same power that TeknoConvey is known for. Best of all, you don’t have to sacrifice your budget in order to protect your business and employees.

If you are unsure if dust ignition proof vacuum equipment is necessary for your application or facility contact us so we can provide a thorough application analysis to ensure appropriate product selection.

TeknoConvey Vacuum Cleaners are suited all ATEX for use in National Fire Protection Association (NFPA) 70: NEC rating Class I, Division 1(Zone 1 only), Groups A,B,C,D T6 and Class II, Division 1, Groups E, F, G T6.

TeknoConvey machines meet the criteria for intrinsically safe operation. No moving parts, non-electric and fully grounded means the unit will not spark or generate dangerous amounts of heat.

These machines are designed also specifically for use in hazardous locations, building in a double safeguard of conductive static dissipative materials and connections coupled with complete grounding of all components of the unit.

Intrinsic Safety

Our explosion proof pneumatic vacuums:

CONTAINS NO MOVING PARTS….. Eliminates possibility of ignition from mechanical friction or contact.

USES NO ELECTRICITY…. Eliminates sparks from motor arcing, shorts, switches and etc.

ARE FULLY GROUNDED….. When an explosion-proof vacuum configuration are configured so that dangerous static electricity will not accumulate.

Intrinsic safety is a protection technique for equipment operating in explosive environments. The principal states that electrical and thermal energy must not build up sufficiently to discharge. With heat or friction risks such as those present when using an electrically operated industrial vacuum safely eliminated, static electricity remains.

The complete grounding of all components, including air supply line, vacuum generating head, dust collecting housing, dolly and vacuum hose ensure that static electricity is continuously dissipated, protecting against dangerous static buildup, which could lead to electrostatic discharge, posing potentially serious consequences when in the presence of combustible substances. TeknoConvey explosion proof vacuum models factory equipped as an explosion proof configuration ensures static electricity will not accumulate.

It is critically important that the operator understand the functions of the grounding system. Inspections are suggested prior to each use to ensure the integrity of all grounding wires and points. Care must be taken to not circumvent any grounding safeguards, and should also be exercised to ensure parts such as hoses aren’t used interchangeably with those from non explosion proof systems.

For price and details please call